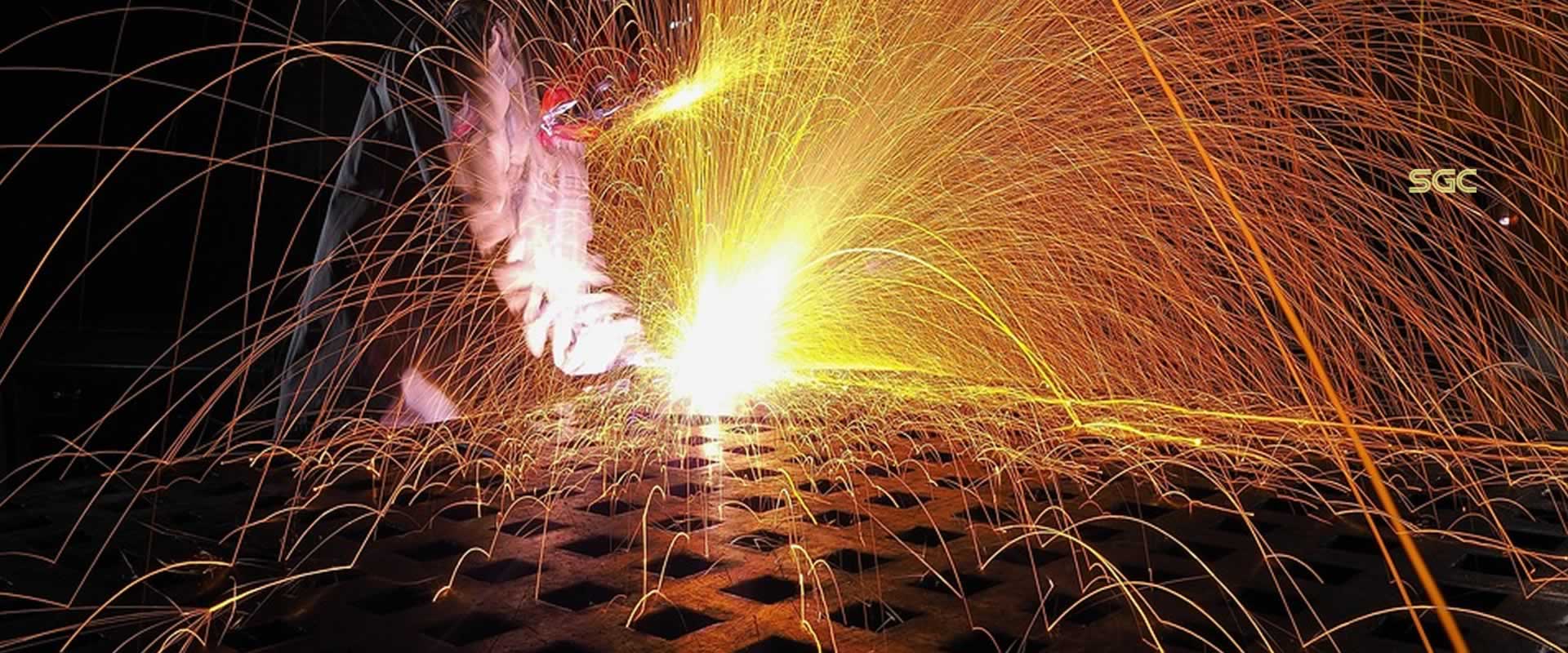

Quality control and safety represent important concerns at SGC. Defects or failures in constructed facilities can result in very large costs. Even with minor defects, re-construction may be required and facility operations im¬paired. Increased costs and delays are the result. In the worst case, failures may cause personal injuries or fatalities. Accidents during the construction process can similarly result in personal injuries and large costs. Indirect costs of insurance, inspection and regulation will increase rapidly due to these increased direct costs. At SGC we ensure that the job is done right the first time and that no major accidents occur on the project.

Our approach for managing quality includes the Quality Plan and three major processes listed below:

Completeness and Correctness Criteria: Our project team and major stakeholders will agree up front on when each major deliverable is com¬plete and correct. The deliverables are then evaluated against these crite¬ria before they are formally approved.

Quality Assurance: Quality assurance activities focus on the processes being used to manage and deliver the solution.

Quality Control: Quality control activities are performed continually throughout our projects to verify that project management and project deliverables are of high quality.

Our quality plan is completed during the planning phase to validate that the major deliverables are completed with an acceptable level of quality.

Our Quality policy is supported by the following companywide objectives:

• Projects within Budget

• KPI – Project Costing and management accounting reports

• Projects on Time

• KPI – Milestones within every project

• Projects with a high level of quality

• KPI – Audit reports and data analysis

|